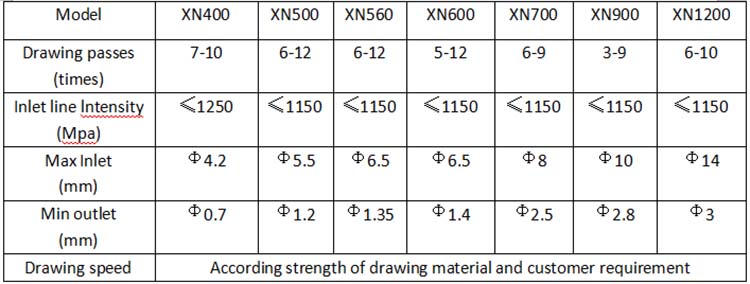

Passing:7-10 / 6-12 / 5-12 / 6-10

Max Dia:Φ4.2 / Φ5.5 / Φ6.5 / Φ14

Min Dia:Φ0.7 / Φ1.2 / Φ1.4 / Φ3.0

Capacity:Custom adjust as clients request

In the nail production process, wire drawing is the crucial first step. The key equipment in a nail making machine system includes the nail making machine, wire drawing machine, straightening machine, and grinding & polishing machine, with the wire drawing machine playing a pivotal role in shaping the wire. The main objective of wire drawing is to reduce the raw wire to the desired diameter for nail production, ensuring the wire remains smooth, uniform in size, and free from bends, while preserving the physical properties of the raw material.

Wire drawing machines are essential for the processing of metal wires. These machines typically consist of wire laying, drawing, water cooling, wire collection, and wire arrangement components. The electrical transmission system is powered by motors for wire laying, wire collection, and wire arrangement. The efficiency and quality of wire drawing are crucial factors for manufacturers.

Wire drawing is a critical process in modern industry, whether for steel wires, electrical cables, or other metal products. Among the various wire drawing machine types, the straight-line wire drawing machine has gained significant popularity due to its reliability, high performance, and user-friendly operation. As a leading manufacturer of wire drawing machines, we offer several key advantages:

High Precision and Durability

Our machines are equipped with advanced technology, including AC frequency control for speed regulation, PLC digital control, and a user-friendly touch screen interface for easy operation and maintenance. This ensures higher production efficiency and reduces overall costs, all while offering an intuitive human-machine interface.

Versatile Applications

Our wire drawing equipment is highly versatile, suitable for a range of applications such as drawing low carbon steel wire, steel cables, galvanized wires, metal meshes, building components, and nail production.

Exceptional Performance

The straight-line wire drawing machine features a multi-pass drawing design, allowing for efficient one-step forming. This eliminates the need for multiple processing stages, reducing production time and boosting overall efficiency.

Preserved Material Integrity

The wire drawing process is optimized to retain the physical strength and inherent properties of the raw material. Thanks to a carefully engineered drawing process, the metal’s performance remains unaffected, ensuring the final product’s quality is upheld.

Simple Operation and Maintenance

Our wire drawing machine is user-friendly, with straightforward operation and easy maintenance. After minimal training, operators can efficiently manage the machine, and daily upkeep is simple, reducing labor costs and overall maintenance expenses.

Stability and Reliability

Designed for long-term use, our wire drawing machine maintains stable operation with minimal breakdowns or downtime. This ensures continuous production, providing a reliable solution for manufacturers seeking cost-effective, high-performance machinery.

Superior Wire Quality Treatment

The machine employs a gentle processing technique during the drawing stage, enhancing wire quality by evenly distributing stress and avoiding localized concentration. This method improves ductility and durability, making the wire more suitable for its intended applications.

Competitive Pricing

We offer excellent value by balancing cost and quality. By using high-quality components and advanced technology, we ensure the performance and durability of our machines while keeping costs manageable. This enables us to offer a competitive price point, ultimately lowering maintenance costs for our customers.