Max dia:3.6

Min dia:1.8

Length:<100

Speed:2900pcs/min / 2400pcs/min

Total cooling power:0.75kw

Motor power:1.8kw

Total installed power:13kw

Weight:1120kg / 1280kg

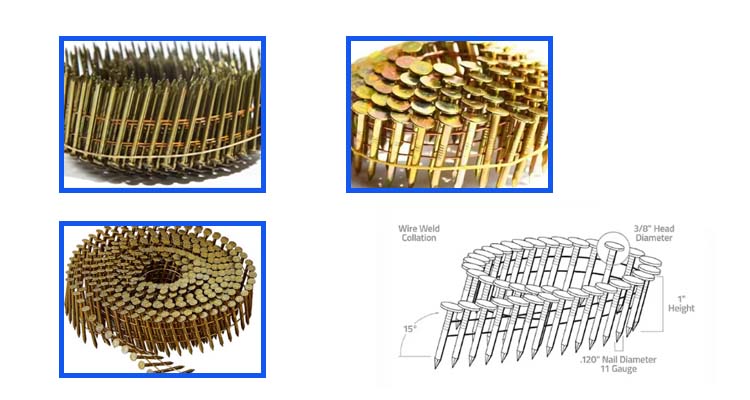

The coil nail manufacturing machine is typically composed of several integrated components and features a high level of automation. It utilizes a vibrating feeder system to deliver raw materials in an organized manner. The primary motor is a variable-speed motor, making it easier to adjust the production speed and perform system calibration, thereby ensuring consistent operation and accurate processing.

The automatic coil nail binding machine comes with an integrated binding mechanism, enabling multiple synchronized processes such as rubber ring feeding and sorting, automated material retrieval and stretching, nail coil alignment, and automatic binding. This setup significantly lowers manual workload and enhances factory automation efficiency.

For welding, the coil nail machine generally employs an inverter-based DC welding power source. This type of power supply offers a steady welding current, rapid operation, and high welding precision. It minimizes issues such as cold welding or detachment. The weld joints and angles remain consistent and accurate, resulting in a smooth final product that operates reliably without jamming.

| Model | JDj-B parameter | JDj-C parameter |

| Max dia | 3.6 | 3.6 |

| Min dia | 1.8 | 1.8 |

| Length | <100 | <100 |

| Speed | 2900pcs/min | 2400pcs/min |

| Total cooling power | 0.75kw | 0.75kw |

| Motor power | 1.8kw | 1.8kw |

| Total installed power | 13kw | 13kw |

| size | 2700*900*1300mm | 3300*900*1300mm |

| Weight | 1120kg | 1280kg |

The automatic coil nail machine offers several key advantages:

Optimized design and streamlined structure

Stable operation performance: Equipped with a dependable control system and high-quality components, it ensures consistent functionality over long periods, minimizing equipment downtime.

User-friendly operation: With automated production capabilities, users only need to perform basic setup and supervision, significantly easing the operational workload.

Enhanced production capacity: It efficiently processes nails into coiled form, substantially accelerating production to meet the demands of high-volume orders.

Consistent product quality: By following preset technical parameters, the machine ensures uniformity in the dimensions, shape, and quality of each coil nail.

High adjustability: The automatic coil nailer allows for tension control adjustments to enhance the alignment and appearance of the nail coils. For instance, some models enable fine-tuning of the mounting base and reducer position via components like screw rods and drive motors, making precise tension regulation possible.

Seamless integration capability: It can be connected with other auxiliary machinery—such as nail-making machines, thread rolling units, or automatic packaging systems—to build a fully automated production line, thus improving overall manufacturing automation.

Flexible adaptability: The machine supports configuration changes to accommodate different sizes and types of coiled nails, allowing it to adapt to diverse production specifications and customer needs.