Nail Diameter:2.0 -5.5 mm

Nail Length:56-130 mm

Out put Speed:620 pcs/min max

Motor Power:11kw +5.5 kw

Size:2500*1400*1400

Weight:3440 kgs

A nail is a widely used metal fastener designed to join or secure materials. Due to their versatile applications, nails come in various forms such as flat-head nails, sharp-point nails, brad nails, screw nails, and thumb tacks. Among these, sharp-point nails are most commonly found in the market and are ideal for connecting wooden elements like furniture frames or hardwood flooring.

However, for industries requiring precision and safety, flat-head nails offer better performance. These nails provide key benefits:

They push forward with a flat tip, minimizing the risk of wood cracking or splitting.

Their design helps reduce debris and splinters, improving the cleanliness of the workspace.

They are safer to handle, reducing the risk of injury during operation.

| item | Specification |

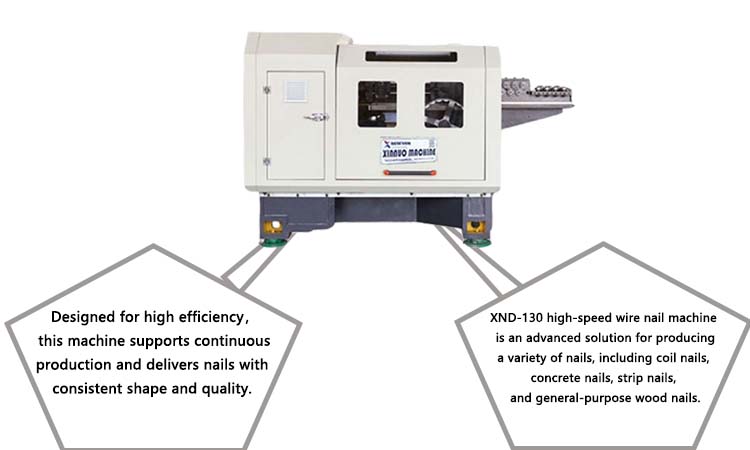

| Product Name | XND-130 High speed wire nail making machine |

| Nail Diameter | 2.0 -5.5 mm |

| Nail Length | 56-130 mm |

| Speed | 620 pcs/min max |

| Motor Power | 11kw +5.5 kw |

| Size | 2500*1400*1400 |

| Weight | 3440 kgs |

XINNUO’s flat-head nail making machines are trusted by manufacturers around the world and have been awarded EU and TUV certifications, proving their reliability and safety standards.

XINNUO’s high-speed automatic wire nail machines are compact, highly responsive, and energy-efficient. Designed for low noise and minimal maintenance, they are widely adopted in sectors like construction and furniture manufacturing for their excellent productivity and precision.

A critical component of these machines is the impact mechanism, which drives the nail forming process. This component functions like the "heart" of the equipment, delivering the force needed for shaping. Enhanced with servo motor drive systems, these machines provide stable, consistent power and long service life.

The working process involves feeding wire into the system, where it undergoes forming, cutting, and shaping into finished nails of various specifications—making it an essential tool in modern production lines.