Nail Diameter:2.0 -6.5 mm

Nail Length:74-160 mm

Out put Speed:800 pcs/min max

Motor Power:11kw + 5.5kw

Size:2960*1460*1400

Weight:4000 kgs

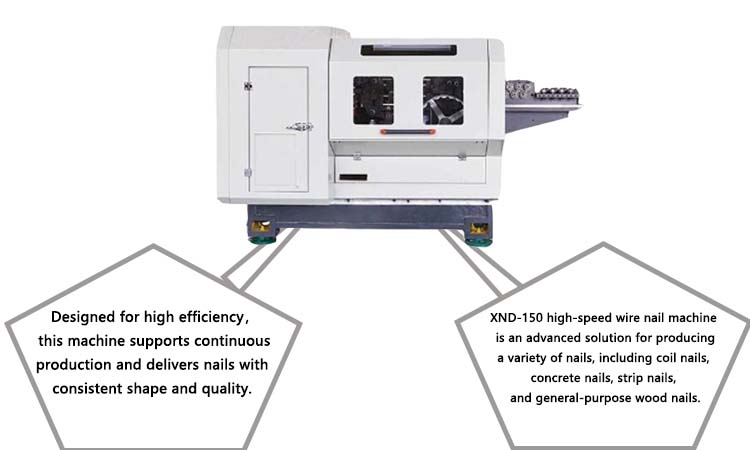

Xinnuo Machinery offers one of the most advanced and efficient nail making machines in the industry. Our latest high-speed automatic nail making equipment ensures quiet operation, precise nail shaping, and impressive production capacity. The system features full automation, including intelligent control via a frequency inverter that adapts feeding speed based on wire diameter and material type.

| item | Specification |

| Product Name | XND-150 high speed nail machine |

| Nail Diameter | 2.0 -6.5 mm |

| Nail Length | 74-160 mm |

| Speed | 800 pcs/min max |

| Motor Power | 11kw + 5.5kw |

| Size | 2960*1460*1400 |

| Weight | 4000 kgs |

This machine is equipped with a self-monitoring function. It will automatically stop and issue an alert in case of wire feeding issues, blockages, length deviations, insufficient lubrication, or overload. It also has an integrated automatic lubrication system, and the entire structure is enclosed to prevent exposure to noise, dust, and operational risks.

Our machines are ideal for producing various nail types, such as common nails, coil nails, D-head nails, paper strip nails, and blind rivet nails. With a maximum output of up to 800 nails per minute, they ensure minimal defect rates—so low they are nearly negligible.

The advanced automation boosts overall productivity and enhances nail consistency while reducing manual labor by over 30%. The coil nail version excels in creating high-quality nails that can be used directly in welding, without the need for pre-sorting.

Thanks to yearly innovations, our machines are now easier to operate and maintain. Using cutting-edge sensors, they support rapid fault detection and quality monitoring. The active wire pay-off system can handle coils up to 1.5 tons, reducing downtime and making production smoother.

The machine’s compact design, low noise output, and extended tool lifespan all contribute to a more comfortable and efficient working environment. Nail waste and finished nails are collected separately, keeping the workspace cleaner and ensuring seamless workflow. Tooling changes allow production of different nail types, including concrete, steel, and specialty nails.